Anglian Water ‘Innovation in practice’

Pressure transient monitoring helped Anglian Water understand how a leak closely became a burst.

Monitoring System Provides Cost-Saving Data to Extend Asset Life

Western Lake Superior Sanitary District (WLSSD) provides wastewater treatment for 17 communities and 3 large industrial facilities in a 530 square mile region in the Duluth-Cloquet (MN) area.

While treating about 14 billion gallons of municipal and industrial sewage annually, WLSSD is committed to protecting the environment, including the region’s most precious resource – Lake Superior.

Preventing sewer overflows and leaks into the watershed is a top priority; pump stations and force mains serve as an effective way to control sewer overflow.

As rising mains are not accessible by camera, they can be notoriously difficult to evaluate. To help develop their asset management plan, WLSSD hired a consultant to evaluate their force mains to identify vulnerabilities in the network.

The consultant conducted measurements and modelling on three rising mains to identify the locations of greatest risk and recommended improvements to reduce that risk.

Based on this analysis, the consultant provided recommendations based on worst-case scenarios, ranging in cost from $185,000 to $1 million in capital improvements.

Faced with this significant investment, WLSSD decided to obtain additional data to verify the model results prior to making capital improvements.

A WLSSD operator suggested using the Syrinix PIPEMINDER-C* transient monitoring system, which he had seen at a conference.

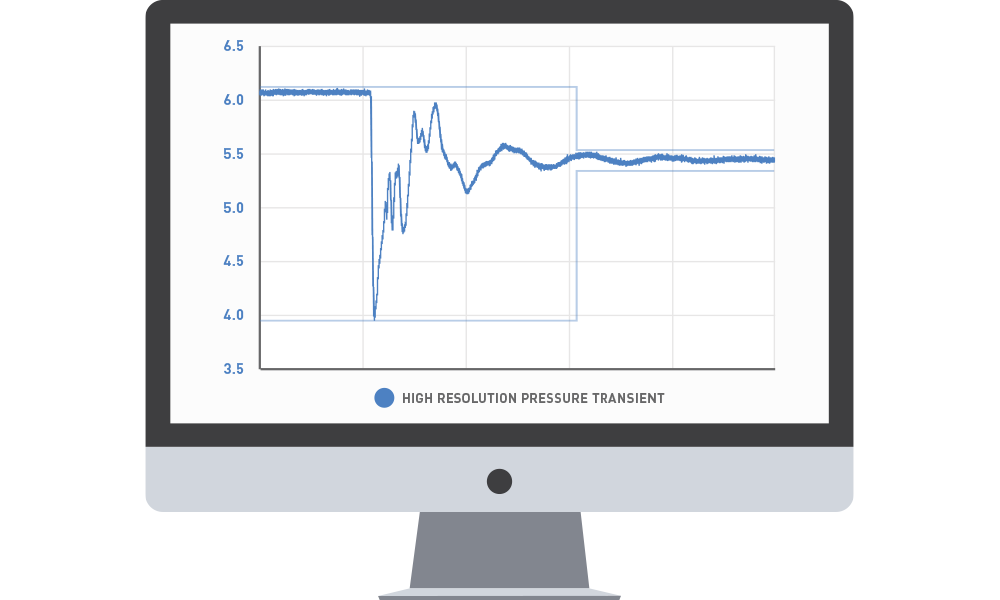

He noted the Syrinix unit’s ability to measure high-resolution transients, down to an absolute vacuum (-14.50 psi gauge), together with its portability, ease of use, and robust support. PIPEMINDER-C is a smart pressure monitor that measures continuously at 128 samples per second.

Data is sent to Syrinix's RADAR cloud data platform, where it is analysed against pre-set network performance parameters. This reveals the system’s operating state, enabling operators to quickly pinpoint issues that can be addressed to extend the life of the network.

*PIPEMINDER-C has evolved to PIPEMINDER-ONE external

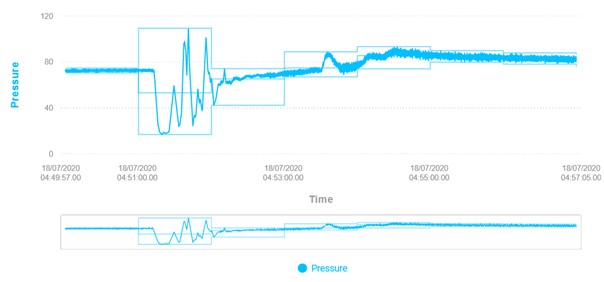

WLSSD installed the PIPEMINDER systems in January 2020. Analyzing multiple locations, they found that the data generated during normal operations lined up reasonably well with the models, as expected.

PIPEMINDER enabled the WLSSD team to verify or identify specific problem areas:

The modeled data revealed this valve was providing limited air transfer to and from the pipe.

PIPEMINDER-C allowed WLSSD to confirm that this component was not critical to force main operations.

The risk of an emergency repair from this connection will be eliminated without detriment to the operation of the system.

At one station, WLSSD had planned to vent an air release valve manhole to improve conditions. Data from PIPEMINDER revealed that this change would not benefit pressures at the station or in the pipeline.

This finding surprised the WLSSD team. Additional work is planned to evaluate whether reinstating a former air release valve location will improve pressures.

PIPEMINDER captured four significant transient events when the pumps shut down due to power failure. Transients were documented and showed significant additional pressure on the pipes that could cause a failure if continued.

This data enabled the team to highlight the importance of determining the cause of the outages and to work with the utility to identify the cause and mitigate the problem.

The information provided to WLSSD from PIPEMINDER, resulted in some valuable benefits:

WLSSD improved its ability to make decisions regarding capital investments and operations backed by accurate data. They now have the information needed to invest resources where there are the greatest risk and the greatest potential benefit.

Data provided by PIPEMINDER now informs capital planning work to improve conditions of WLSSD’s force mains.

While modeling is important, the results may not reflect actual conditions. Modeling that is too conservative can lead to unnecessary capital expenditures. Having accurate monitoring data helps WLSSD identify smaller capital projects that extend pipeline life—and to see where additional protection is not warranted.

Industrial and residential customers rely on WLSSD’s systems 24 x 7. Shutting down a pipeline due to transient events or component failures is not an option.

By proactively identifying potential problem areas using data generated by PIPEMINDER, WLSSD can take steps to reduce the risk of operational interruptions.

The WLSSD team found the PIPEMINDER-C and RADAR platform very user-friendly and easy to install, maintain, and evaluate. Syrinix support was excellent.

Their only wish? 16 more units: one for each pump station.

Watch an interview with Senior Engineer Dianne Mathews PE as she explains her story to Water & Wastewater Digest

Pressure transient monitoring helped Anglian Water understand how a leak closely became a burst.

Anglian Water generate workable data and cost savings on rising mains

South-East Water – Acoustic & pressure monitoring help to both find and prevent leaks.

Leave your details and we will be in touch.