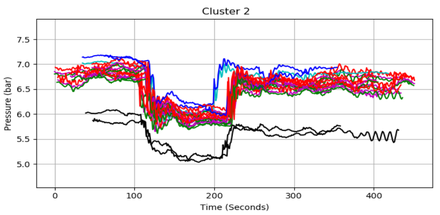

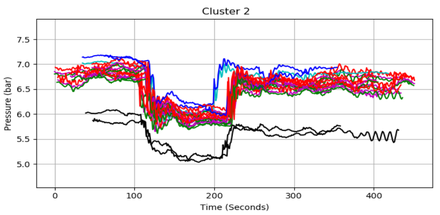

Shape Classification

Shape classification can automatically classify the type of transient and alert by exception for unusual events

What is a transient? and why exactly should we be worried about them?

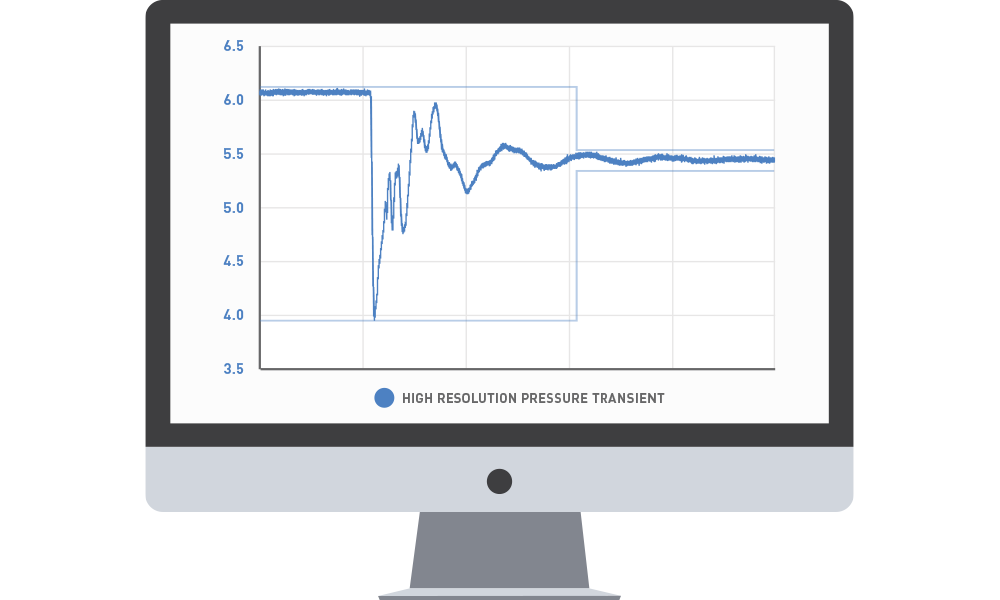

Commonly known as ‘water hammer’, transients are short-lived pressure waves delivering fast changes in the pressure of a pipe in water networks.

Usually caused by network operations such as closing a valve or sudden pump shutdowns, transients are proven to cause stress and fatigue on pipelines and assets as they propagate through the network, ultimately leading to cracks, leakage and bursts.

Data collected from monitoring pressure transients can be interpreted in order to pre-empt pipeline fatigue and used pro-actively to reduce leakage, prevent bursts, and ultimately extend asset life.

This means improved repair planning, water loss reduction, and avoiding emergency repair costs.

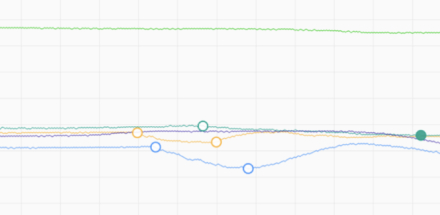

PIPEMINDER-ONE combines accurate pressure monitoring at 128 samples per second, with high accuracy network synced time stamping and the application of a patented 'S3' severity scoring system, which grades the severity of all transient activity.

All data is displayed in Syrinix's cloud data platform RADAR and using the S3 scoring algorithm, alerts to unusual pressure events are triggered, in order that information can be tracked, reviewed, and acted on.

By capturing high-resolution, time synced data, PIPEMINDER can detect events that other systems may miss. It also stores and uploads this data for 30 days, enabling detailed analysis of past events.

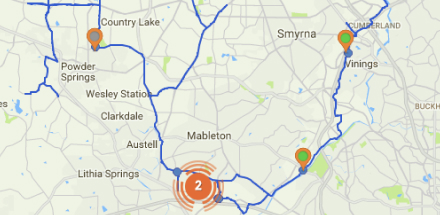

Accurate time synchronisation across multiple monitors enables RADAR to automatically triangulate the source of events.

High-quality data outputs are sent swiftly over a future-proofed cellular connection that can make use of 4G 3G and 2G networks.

Quality and trusted management information is ensured.

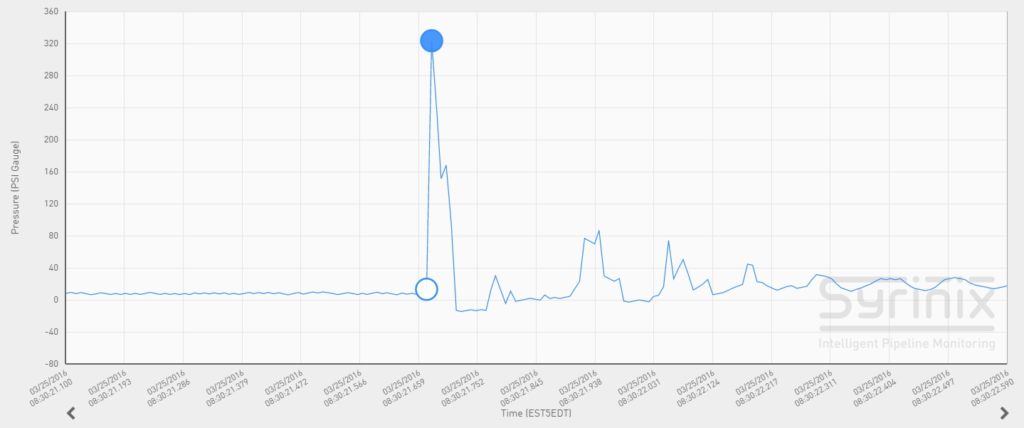

Las Vegas Valley Water District (LVVWD) experienced three pipeline bursts in close proximity and installed PIPEMINDER devices to understand why.

Data collected from PIPEMINDER sensors and analysed in Syrinix's RADAR data cloud platform revealed LVVWD was experiencing harmful transients, with ranges exceeding 300 psi: twice that of the PVC pipeline's maximum pressure rating of 150 psi.

When this transient data was overlaid with utility SCADA system data, it was clear that the transient activity correlated with valve operation activity within the network.

The visibility of this information meant LVVWD could make changes to their valve operations.

This calmed the network, mitigated the risk of further breaks, and prolonged the life of their main.

Talk to Syrinix about transient detection and the benefits of calming down your water networks.

Shape classification can automatically classify the type of transient and alert by exception for unusual events

CCMWA wished to gain greater visibility and insight ito discover exactly what was going on within their transmission loop.

The leakage team came to Syrinix to look at new ways of understanding what was going on within their DMAs.

Leave your details and we will be in touch.