Syrinix worked with CCMWA to help them understand exactly what was happening on their network

Cobb County Marietta Water Authority

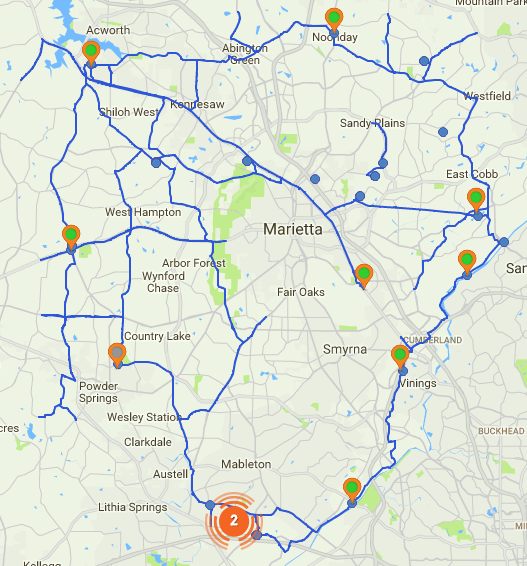

Cobb County Marietta Water Authority (CCMWA) has a large diameter transmission main loop carrying water around its jurisdiction. The loop is 75 miles long, with pipe diameters of 36 to 54-inch diameter and consists of both ductile and PCCP material.

Undertaking condition assessment inspections or installing a typical leak detection monitoring system for the full length of the line was deemed cost prohibitive for the utility, therefore CCMWA deployed ten PIPEMINDER-S devices to find out exactly was going on in their loop.

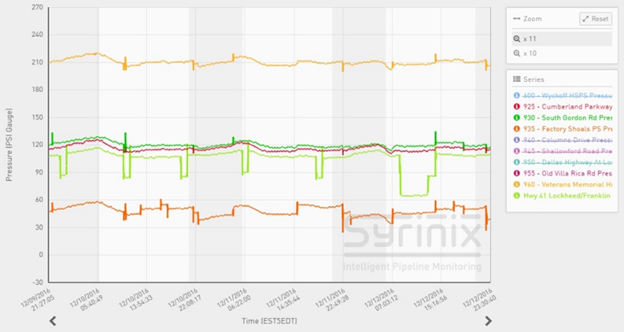

To better understand a water utility network, regular and expected pressure events from normal operation must be gathered. This data acts as a benchmark for anticipating how the network will act under various conditions and highlights any pressure events which are unexpected.

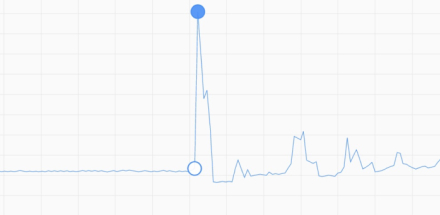

Once the correlation between changes in infrastructure and pressure events in the system are understood, transients and surges which do not correspond to operational changes become much more interesting.

This implies that the pressure event is associated with something not presently controlled, and either could lead to damage or could indicate that damage (e.g. a burst) has occurred.

Broken valve actuator

A pressure drop of approximately 40 psi corresponded to 3000 gpm demand on the system, but a 36-inch DIP should be able to provide 3000 gpm with only a small pressure drop.

After a coordinated field-testing effort, it was determined a 36-inch butterfly valve had a broken actuator, leaving the disk in a nearly closed position all the time, regardless of the apparent valve actuator position. The other pressure events shown in this graph at other monitoring locations are attributable to known pump and valve operations.

Knowing this, the pressure events measured at this monitoring location were easy to interpret as abnormal events and could be attributed to the broken actuator.

An extended read of the work between Syrinix and Cobb County Marietta Water Authority was published in AWWA Opflow in September 2020.

More case studies

Las Vegas Valley Water District ‘Main break investigations’

LVVWD experienced 3 line breaks in close proximity and installed PIPEMINDER devices to understand why.

Contact Us

Leave your details and we will be in touch.