Canal de Isabel II ‘Transmission main pilot’

Spanish utility company undertook investigative work on their Madrid mains

Why acoustic monitoring for leak detection gives you confidence that your critical pipelines are in safe and assured hands.

It is estimated that of all bursts that occur on cast iron pipelines, 80% begin as a leak. With little or no monitoring on trunk mains, emergent leaks can gather speed but remain undetected.

Utilities may choose to inspect their pipelines routinely via varying survey methods however some technologies only create a snap-shot on that given day.

Establishing a longer monitoring period and installing confidence in data collection is key before the pipeline is discounted as having any pre-existing leaks.

Working in paired units or as a string for longer distances, PIPEMINDER collects acoustic data up to four times daily, automatically assessing pipelines to quickly and accurately understand the integrity of the monitored main and identify and report any new leaks.

The additional collection of high-resolution pressure data identifies pressure transients that could contribute to pipeline fatigue and can even be a cause of emergent leaks.

Using acoustic sensors for enhanced correlation, the data over time builds a detailed picture of the state of the monitored main.

Multiple sets of acoustic data are collected, reviewed, and monitored via RADAR, our cloud data platform, and confidence-based alerts, with built-in false positive mitigation, are reported.

Depending on the criticality of the monitoring site, PIPEMINDER systems can either be left in situ for complete 24-7 coverage or can be moved to other pipelines.

The addition of PIPEMINDER pressure monitoring sensors at shorter intervals on the trunk main also enhances understanding of how the pipeline is operating.

In Madrid, PIPEMINDER was piloted for leak detection capabilities on different pipeline dimensions and materials and in both quiet rural and noisy urban environments.

Leaks were simulated in blow off chambers whilst a correlation was run.

A rural test was conducted to test the limitation of inter-sensor distance and the impact of bends which reduce how far in distance acoustic noise will propagate.

The result was a positive correlation over a distance in excess of 3.3km. Full story here

Talk to Us about how we can advise you on an acoustic leak detection strategy

Spanish utility company undertook investigative work on their Madrid mains

Syrinix has launched a new video highlighting the benefits of PIPEMINDER monitoring and the analytical tools in RADAR

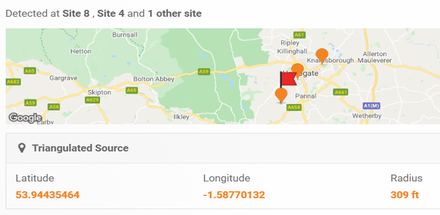

With RADAR’s triangulation feature, identifying the source of a transient is now automated.

Leave your details and we will be in touch.