Greenville Utilities Commission

Optimizing Pressure Transient Monitoring With Data-Driven Monitor Placement.

The City of Galveston Uses PIPEMINDER Pressure Monitors to Revitalise System and Improve Resilience

For The City of Galveston, the summer of 2022 marked the biggest vacation season since before the pandemic, ballooning the island’s population from 50,000 to 250,000 from May to September.

While the volume of water was not a problem, the City’s water utility struggled to get water to shifting areas of high demand.

Syrinix PIPEMINDER-ONE pressure monitors proved to be a key element of the solution.

In the autumn of 2021, the utility reached out to a trusted manufacturer’s representative, HydroPro Solutions, who turned to Syrinix to pilot PIPEMINDER pressure monitors.

This was very good timing in light of the city’s growing customer complaints about low water pressure.

The Director of Public Works and Utilities, Trino Pedraza agreed to the pilot, and in September 2021, three PIPEMINDER units were installed, followed by six additional.

All of which were placed in various trouble spots across Galveston Island.

As these began to deliver increased visibility of the system, the utility also launched an initiative to get SCADA back online which was completed in the spring of 2022.

Post-pandemic vacationers push the utility past its limits; Galveston puts two data streams to work

Enter the summer of 2022, when vacation crowds descended on Galveston in a manner not seen since pre-pandemic days.

Cruise liners arrived to refill their water tanks, guests packed into hotel rooms, restaurants filled with customers, hospitals returned to normal treatment and operations of patients, and suddenly the utility began to have significant demand issues and became inundated with calls about low water pressure.

Getting better, real-time information from the water distribution system became a top priority.

It was at this time that the City of Galveston realized they had the exact tools they needed to solve their problems: a network of Syrinix PIPEMINDER-ONE Hydrant mounted pressure monitors and a working SCADA data acquisition system.

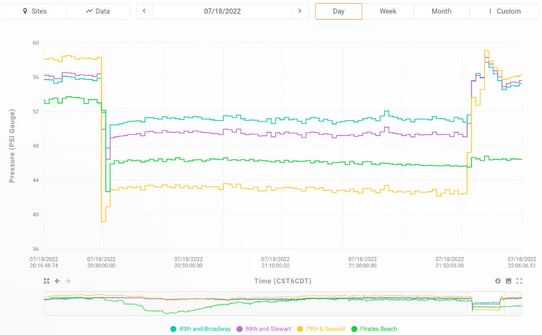

Now with a total of 12 PIPEMINDER pressure monitors, they strategically redeployed them to targeted hotspots up and down the 32-mile coastline and saw with great clarity how the information they had been receiving could help them understand system pressure and better control water traffic.

Methodical coordination of components to optimize the water system

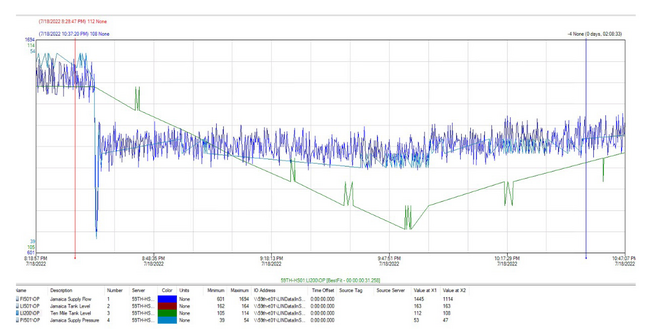

First the utility increased the frequency of data delivery from the pressure monitors, which showed the impact of their actions, such as turning on and off pumps and opening and closing valves.

Second, they made some adjustments to their SCADA system, which at the time was only looking at existing pressure monitors right outside the pump stations and which did not account for pressure issues elsewhere in the system. This setup also meant that if one pump station lost power, entire zones lost system pressure.

Third, what they learned from the increased visibility between the PIPEMINDER pressure monitors and recalibrated SCADA system allowed them to make major operational changes that previously were considered too risky, due to the lack of information. This included being able to run both their east-end pump stations simultaneously, which greatly increased the capacity of the existing system.

Finally, the utility learned how to optimize the alert system that would help them solve problems before they impacted the customer.

The process took about six weeks, an information overhaul for the City of Galveston that improved resilience and delivered significant benefits for the water utility and its customers.

Thanks to remarkably better data, the utility now can lose power at one pump station but maintain pressure throughout the system.

As an example, a power surge from the local power utility caused the unmanned pump station to shut down in mid-July of 2022. A PIPEMINDER pressure monitor near that pump station alerted the utility when the pressure fell below a preset threshold of 40 PSI, and technicians were dispatched to the station, determined the cause of the problem, and restarted the pumps, getting the station back online.

In the meantime, due to optimization adjustments already in place to coordinate the SCADA system and the pressure monitors, the overall system maintained pressure with water from a small, elevated storage tank and when that water ran low, another pump station compensated for the loss of the initial pump station until power was restored. This all happened so quickly that customers were never aware of the problem.

The utility also now has a much better grasp on the water “habits” of the island, such as the irrigation schedules of large subdivisions and the cadence of cruise ships coming into port, knowledge that is helping them adjust their patterns to prevent pressure loss in other parts of the system due to these demand spikes.

Another benefit from the increased system visibility was the ability to test certain parts of the system with less fear of failure. The network of pipes, pumps, and valves is aging, and being able to isolate specific parts to check their functionality has been especially valuable with regard to being able to plan system improvements.

From a customer service perspective, the utility experienced a 63% decrease in low-pressure calls between the month of July 2021 and July 2022.

This case study was published in the March issue of - Trenchless Technology

Optimizing Pressure Transient Monitoring With Data-Driven Monitor Placement.

Leave your details and we will be in touch.