City of Galveston

Case Study – City of Galveston uses PIPEMINDER-ONE pressure monitors to revitalise its system and improve resilience

Optimizing Pressure Transient Monitoring With Data-Driven Monitor Placement

The Greenville Utilities Commission (GUC) provides electric, water, sewer, and natural gas services to more than 135,800 customers in Greenville and across Pitt County, North Carolina. The utility’s distribution network is composed of approximately 70% polyvinyl chloride (PVC), 20% asbestos-cement (AC) and 10% cast iron pipelines. Providing a reliable supply of water while effectively managing costs is at the core of the utility’s mission.

Like many water utilities, GUC has prioritized reducing leaks throughout its network. Just as critical is the need to avoid water main breaks that can lead to significant water loss, causing loss of revenue and requiring costly repairs.

GUC was challenged by pressure transients that cause damage to network assets leading to leaks and water main breaks. One such break occurred on a weekend night, and it took hours for the utility crew to locate the leak by driving around the service area. While the break was eventually discovered in a 14-inch main in an out-of-the-way industrial location, GUC management realized they needed a better solution for proactively mitigating pressure transient problem areas and for rapidly and accurately locating breaks. Speedy response time is critical to minimizing the impact on customers and costly water loss.

While GUC had pressure monitors deployed at various locations in the network, they did not have the ability to detect and triangulate the source of pressure transients. Recognizing that improved pressure transient monitoring was needed, GUC management turned to Syrinix and faced the challenge of where to place monitors to best inform its network calming efforts.

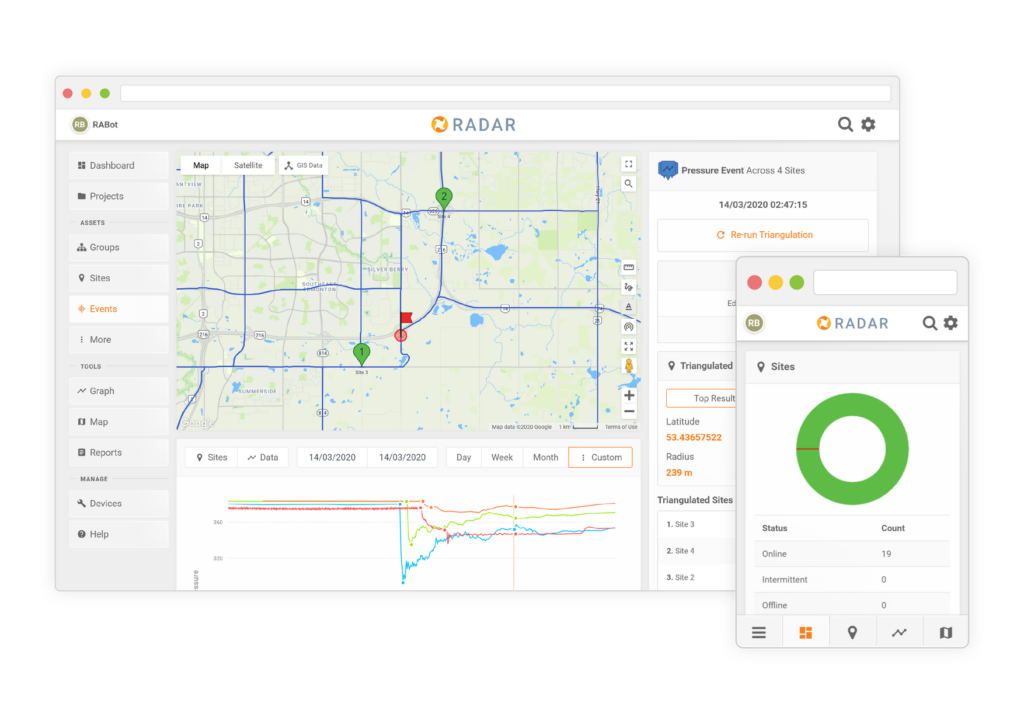

RADAR, Syrinix's cloud platform deployment planning software tool allowed utility engineers to identify the optimum locations for monitoring deployment to maximize coverage for pressure transient monitoring and network management and analysis.

The tool simulates different transient event sizes and calculates wave propagation across proposed locations and analyzes pressure wave attenuation and predicts impacts at various network locations. Using geographic information system (GIS) data, it produces color-coded coverage maps to inform decisions about optimal monitor placement.

Monitors were then deployed according to the guidance provided by the planning tool.

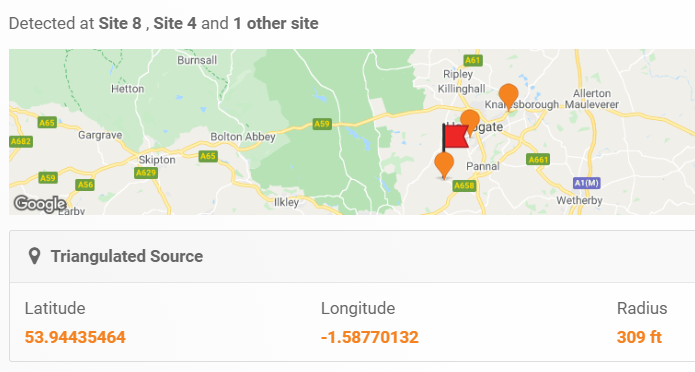

As pressure drops due to a leak, RADAR analyzes data from the PIPEMINDER-ONE monitors to triangulate the source location. Triangulation is achieved when a transient event is detected using more than two sensors, each offering a precise time-data point.

With an integrated GPS receiver recording the unit’s position, an algorithm is applied to the data, pinpointing the location and immediately alerting the utility. GUC deployed a total of 22 units throughout its network monitoring approximately 725 miles of pipe.

The combination of optimal monitor locations and triangulation analysis creates a smart network where pressure and acoustic data is analysed in real-time, enabling a rapid response to potential leaks and bursts to speed mitigation, while minimizing the need for continuous human monitoring.

Monitoring is enhanced by the Syrinix systems working to an “S3” severity score, a computed measure of pressure change severity over a specified time period. Significant changes result in a high S3 score, while small changes over the time period measured produce a lower score. A continuously stable pressure results in an S3 score of zero. Using S3 scoring, alerts to unusual pressure events are triggered, so information can be tracked, reviewed, and acted on.

For example, GUC staff were able to identify where valves were closing too quickly and creating pressure waves. Armed with this insight, GUC staff mitigated the issue by changing to valves based on newer technology. This produced an immediate reduction in transients being pushed to the distribution network, which would otherwise stress the system, improving network performance and reliability.

Based on its success to date, GUC is looking to make data-driven network monitoring a key element in its operational strategy.

GUC is looking toward a future where advanced technology and data analysis inform decisions that drive continuous improvement in service reliability, efficiency, and environmental responsibility.

This story was recently published in Pumps and Systems

Case Study – City of Galveston uses PIPEMINDER-ONE pressure monitors to revitalise its system and improve resilience

Leave your details and we will be in touch.