Syrinix solutions empower water utilities to make operational changes. By increasing efficiency and long-term resilience, utilities can reduce disruptive leaks and bursts. Contact us to discuss and view Case Study examples below.

Save costs and increase resilience

Cost-effective detection for failures

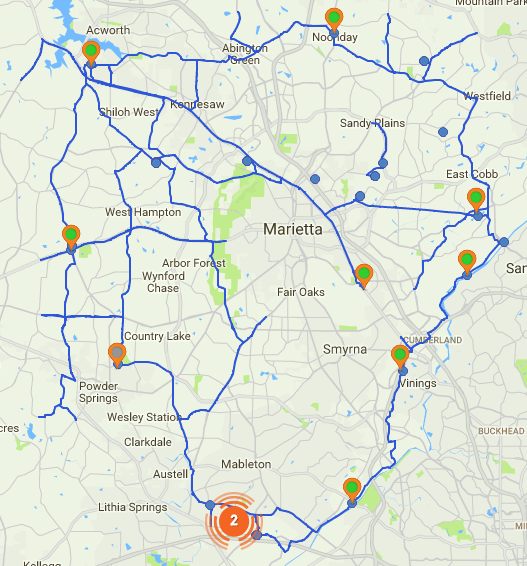

With a ring main loop of transmission mains of approx. 200 miles serving 850k end users, Cobb County Marietta Water Authority had suffered several sudden 6-12” tapping saddle failures.

Each of these events created an orifice flow condition that limited the leak rate to that of flow, meaning large scale leaks were not detected.

Following the installation of PIPEMINDER devices, over a six month period, Syrinix alerted the utility to several abnormal events, meaning that better planning and more informed asset repair and management decisions could be taken.

A rural solution

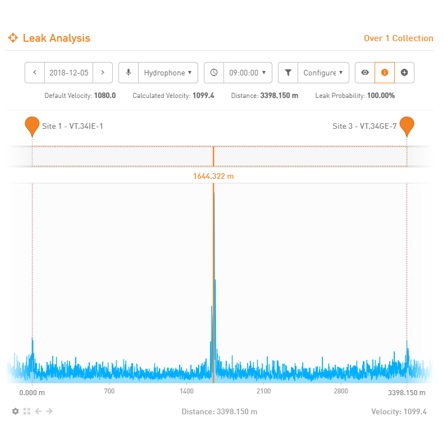

In Madrid, Canal de Isabel II was seeking a leak detection solution that would alert for any pipe breaks which could go undetected.

A pilot project using PIPEMINDER-T to investigate leak detection capabilities on different pipeline dimensions and materials, and in both quiet and noisy environments was commissioned

A rural test looked at the limitation of inter-sensor distance and the impact of bends which reduce how far in distance acoustic noise will propagate.

The result delivered was a positive correlation on a blind leak test over a distance in excess of 3.3km

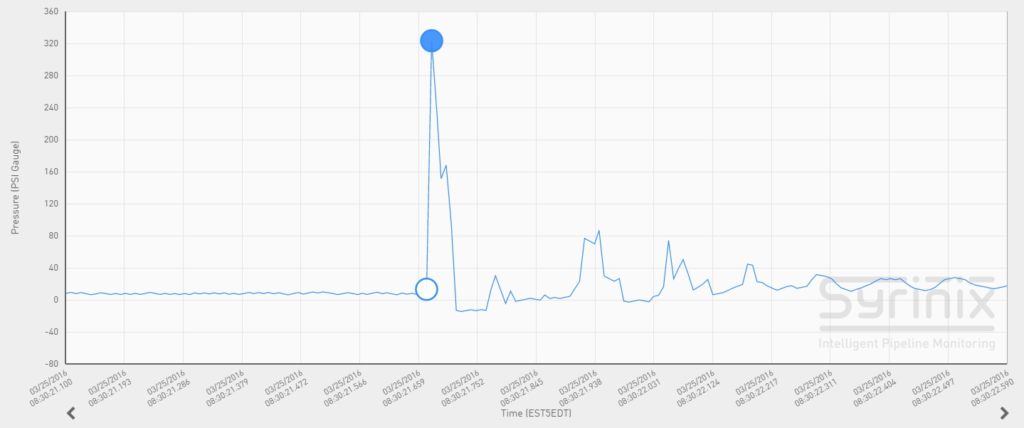

LVVWD experienced costly pipe breaks and were keen to understand why.

Data collected from PIPEMINDER sensors and analysed in Syrinix's RADAR revealed LVVWD was experiencing harmful transients, with ranges exceeding 300 psi: twice that of the PVC pipeline's maximum pressure rating of 150 psi.

When this transient data was overlaid with utility SCADA system data, it was clear that the transient activity correlated with valve operation activity within the network.

The visibility of this information meant LVVWD could make changes to their valve operations.

This calmed the network, mitigated the risk of further breaks, and prolonged the life of their main. Read the full story here

Contact Us

Leave your details and we will be in touch.