Force main monitoring

Brand new learnings from pressure monitoring on force main wastewater networks

Interesting happenings within the Anglian Water network

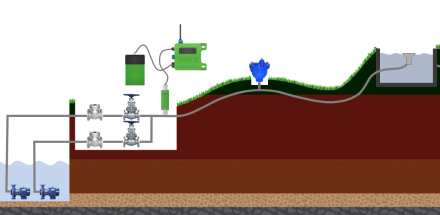

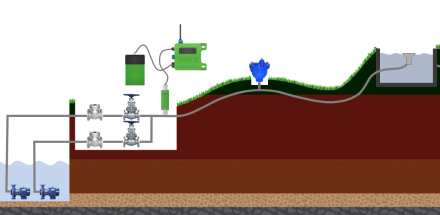

Syrinix worked with Anglian Water within their innovation hub area termed ‘Shop Window’, deploying PIPEMINDER-S sensors on a section of PVC pipe with a history of bursts between a pump station and a water tower.

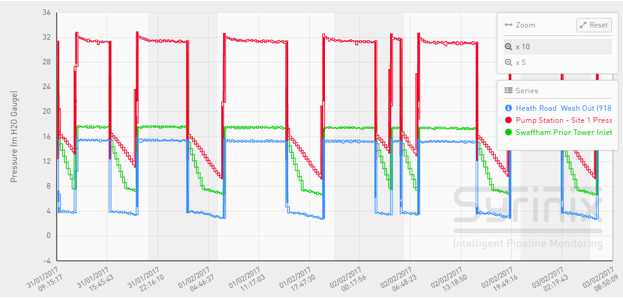

It was soon noted that when pumps were off, pressure was dropping at the pump station, suggestion that water was being lost within the system.

Analysis estimated a leak of 1-2l/s was evident and in reviewing the network pressure profile within Syrinix's RADAR data hub it was possible to triangulate the leak to a specific section of the pipe.

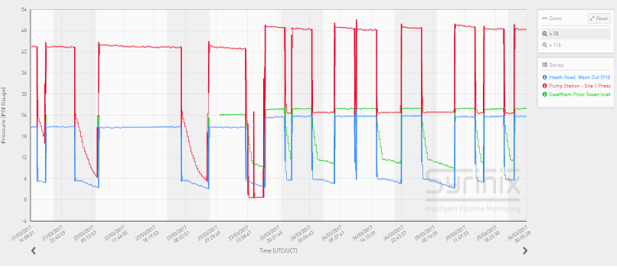

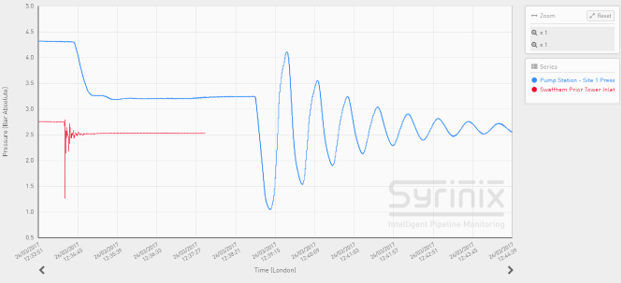

Anglian Water repaired the leak meaning the pressure held stable. However, there was a knock on effect in that the new maintained pressure, increased the stresses on the (by then) fragile main and three days later the pipe burst.

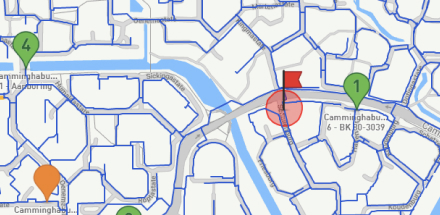

The onset time of the burst detected at each monitored site, is a function of the distance from the burst and the wave speed of the pipe and when this is overlaid with accurate GIS data it is possible to triangulate the burst location.

For this burst, the estimated location given to Anglian Water by Syrinix was 22m from the true burst location.

Not only could we identify and solve pre-existing issues such as the leak, but we can also have constant accurate monitoring for future events, such as the burst main.

Brand new learnings from pressure monitoring on force main wastewater networks

Vitens implemented a pilot project on the impact of pressure transient monitoring

The City of Galveston Uses PIPEMINDER Pressure Monitors to Revitalize System and Improve Resilience.

Leave your details and we will be in touch.